- Ukuhanjiswa Forgings

- Metallurgical oomatshini Forgings

- Amandla Okwenza Amacandelo Omoya

- Amacandelo okwenziwa kwe-Steam Turbine

- I-oyile neGesi -Isiphelo solwelo lweMpompo

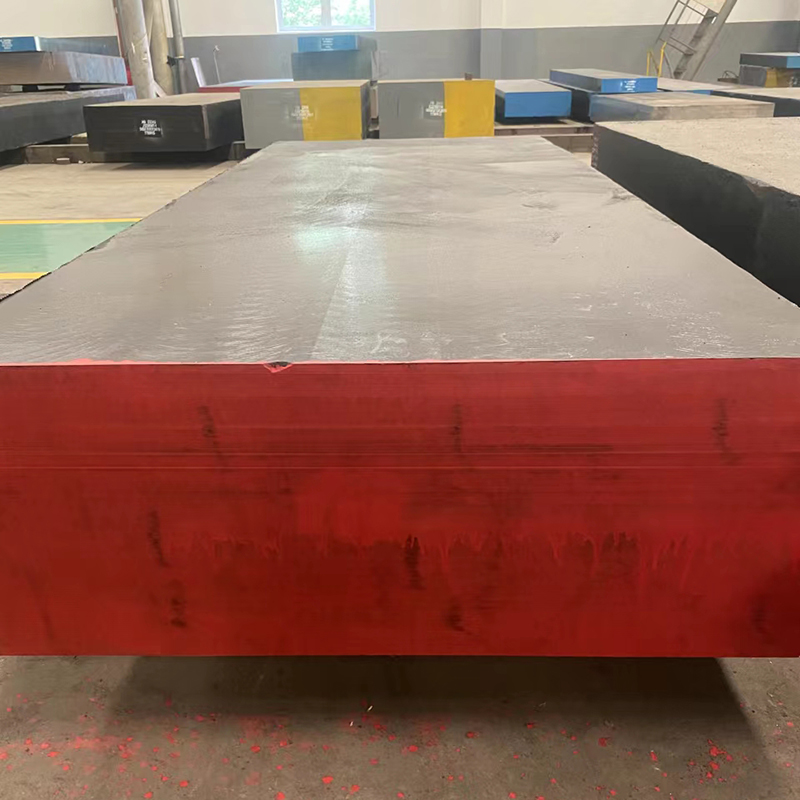

- Die Steel Products

- Amacandelo Okwenza oomatshini bemigodi

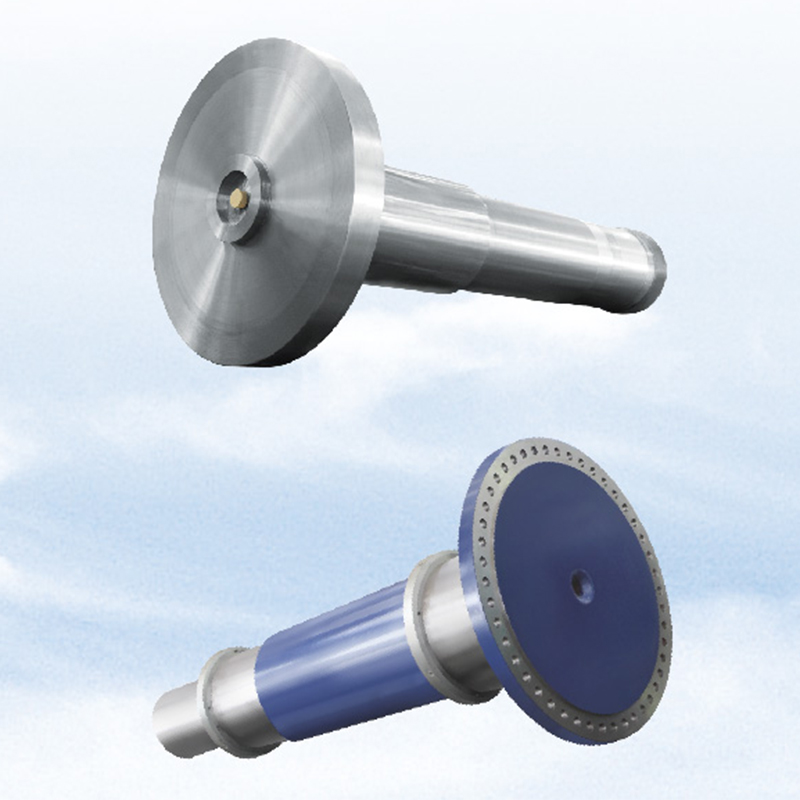

- I-PaperMaking-Shaft Rotor

- Hydro Power forgings-Turbine Shaft

- Ulwakhiwo lweenqanawa zoKwakha iiNdawo

0102030405

Metallurgical oomatshini Forgings

inkcazelo2

INKCAZO

Ngeemveliso zethu, unokulindela ubugcisa obuphezulu kunye nokuthembeka. Ukubunjwa ngakunye kuveliswa kwimigangatho yemathiriyeli ehamba phambili kwishishini efana ne-EN10083, EN10084, EN10085, EN10088 kunye ne-EN10250, ukuqinisekisa ukuba eyona migangatho iphezulu yomgangatho iyahlangatyezwa. Imathiriyeli ekrwada ye-forgings yethu iveliswa kusetyenziswa itekhnoloji ephezulu efana ne-EAF+LF+VD+ingot casting (i-bottom casting), kwaye imveliso yokugqibela yomelele kwaye ithembekile.

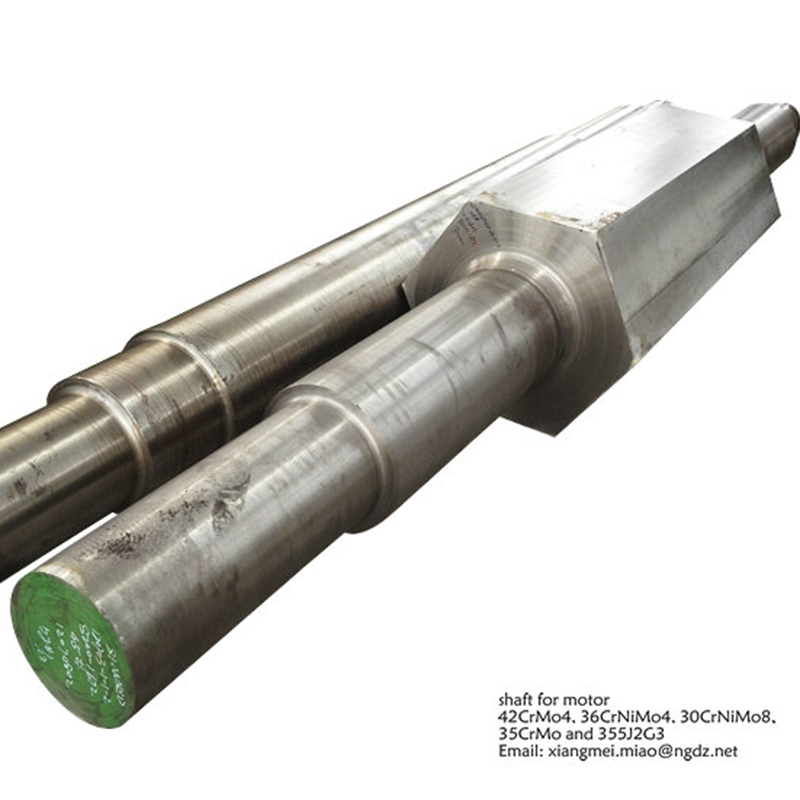

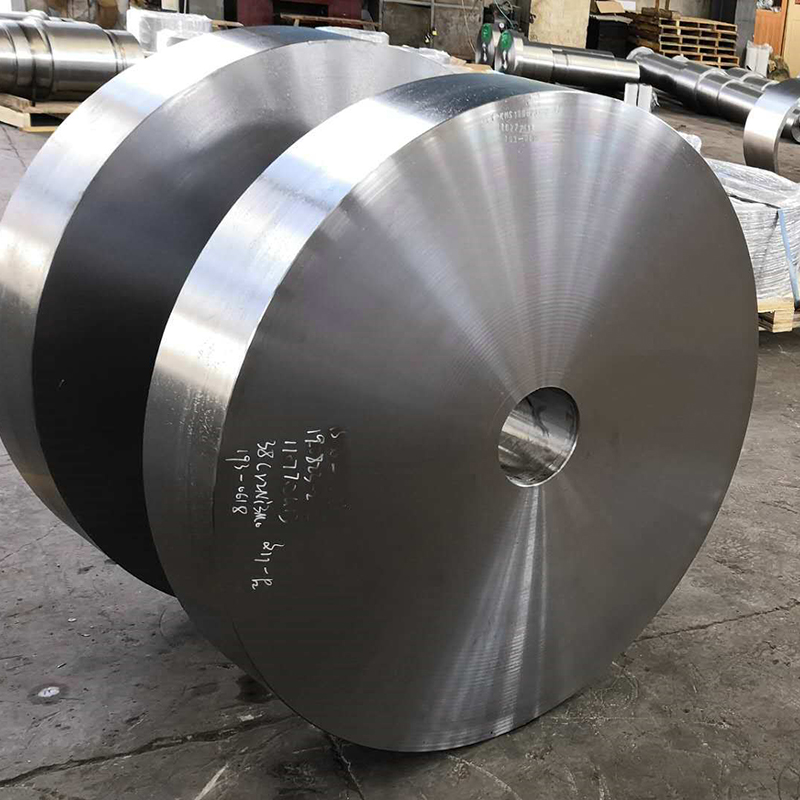

Umatshini wethu we-metallurgical forgings unoluhlu olubanzi lwezicelo. Nokuba ufuna i-rotors, shafts, rollers, crankshafts, spindles, eccentric shafts, bevel gears, gears, parallel pinions, flanges, Crowns, bushings, sleeves, couplings or crank arms, sineemfuno ezigqunyiweyo. Uluhlu lwethu olubanzi lweemveliso luqinisekisa ukuba sinokuhlangabezana nazo zonke iimfuno zakho ezithile, nokuba zintsokothe kangakanani na.

Enye yeempawu eziphambili zokwenziwa koomatshini bethu besinyithi ngumyinge wokubumba. I-forgings yethu iveliswa ngokuchaneka kunye nokuchaneka ubuncinane kwe-3: 1 okanye ngaphezulu. Oku kuqinisekisa ukunyaniseka kwesakhiwo kunye nokuphucula ukusebenza ngokubanzi kwemveliso egqityiweyo.

Ukuze kuphuculwe ngakumbi amandla kunye nokuqina kwe-forgings, sifumana inkqubo engqongqo yonyango lobushushu. Oku kubandakanya ukunyanzeliswa, ukucima kunye nokufudumala, unyango lwesisombululo sensimbi engenasici okanye uxinzelelo lwe-rotor okanye shaft. Ezi nkqubo zinceda ekudaleni i-metallographic efanayo kwaye ingaguquguqukiyo, ekhokelela kwi-forgings ekwazi ukumelana kakhulu nokuqhekeka, i-spalling, i-shrinkage cavities, i-pinholes kunye neengxaki ze-welding.

Ukuze siqinisekise umgangatho wokubunjwa, sithobela imigangatho yesakhiwo se-ASTM E45 ye-metallographic. Oku kuqinisekisa ubungakanani bengqolowa ye-5 okanye engcono, ebonisa i-microstructure efanelekileyo kunye neyunifomu. Siyazingca ngokubonelela ngenkohliso engenaziphene kunye nokungafezeki, kukunika uxolo lwengqondo ukuba iimveliso zethu ziya kusebenza ngokugqwesileyo kwisicelo sakho.

Lilonke, oomatshini bethu bokwenza isinyithi babonisa ukuzibophelela kwethu ekunikezeni umgangatho kunye nokusebenza okuphezulu. Ngoluhlu olubanzi lwezicelo, izixhobo ezikumgangatho ophezulu, iindlela ezichanekileyo zokuvelisa kunye nemilinganiselo yokulawula umgangatho obanzi, ukukhwabanisa kwethu kolona khetho lungcono kuyo nayiphi na imfuneko yomatshini we-metallurgical. Khetha i-forgings yethu kwaye ube namava umahluko ekusebenzeni kunye nokuthembeka.

Ekhaya

Ekhaya