0102 ib0304 ib05

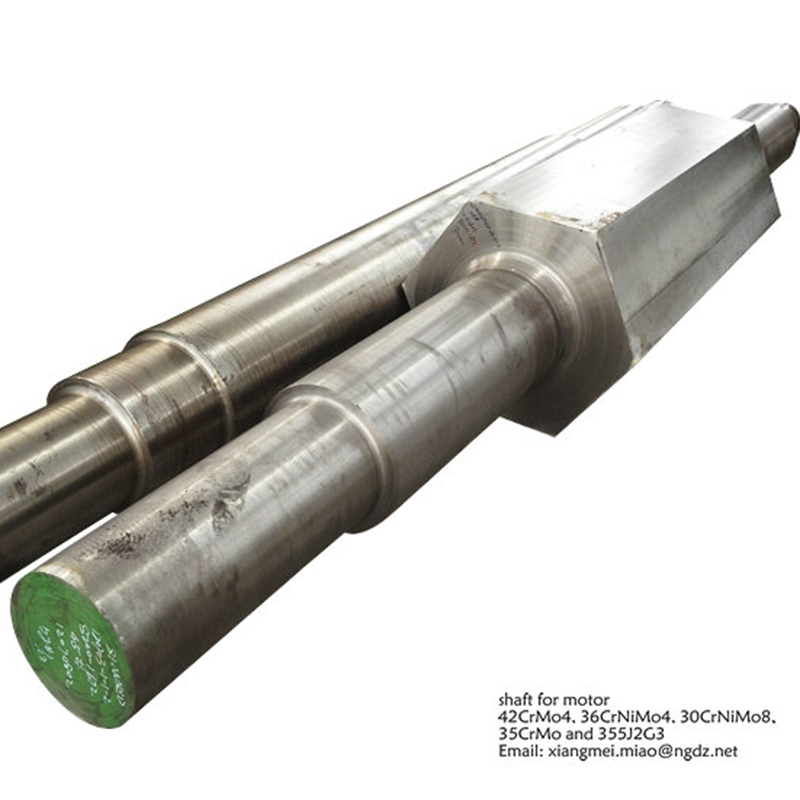

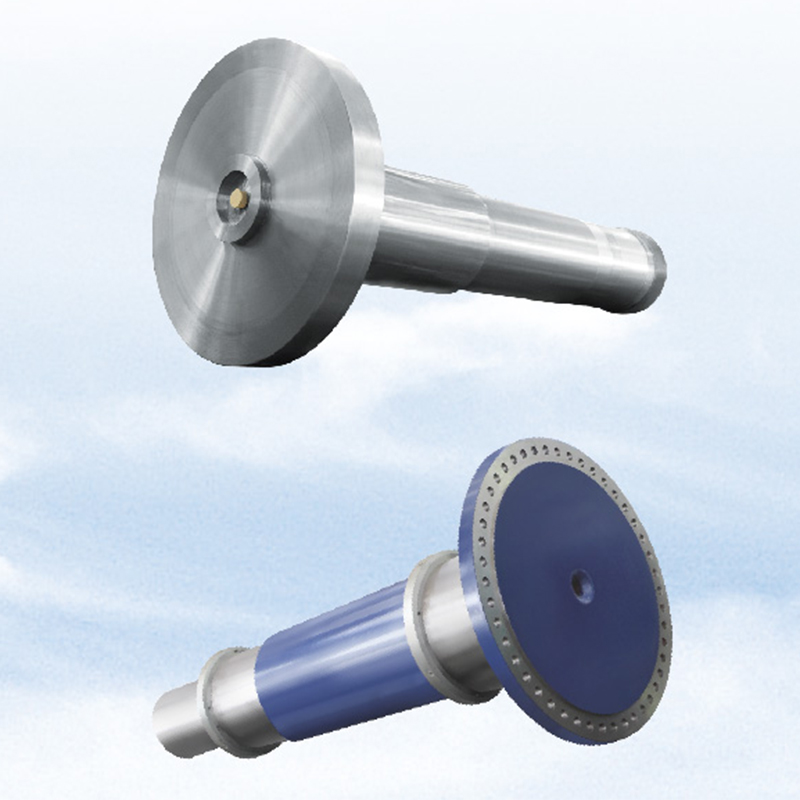

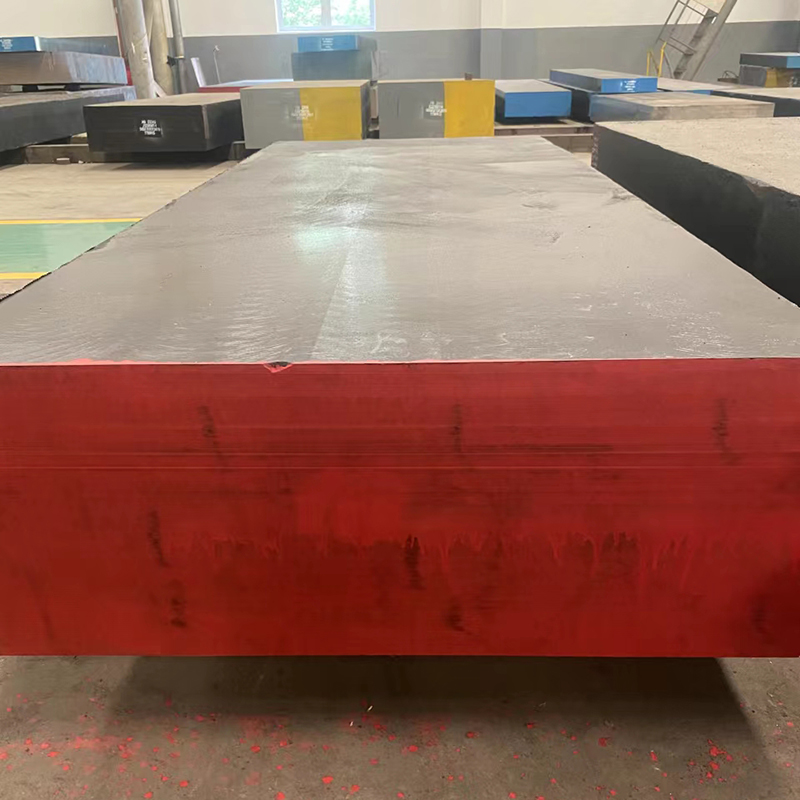

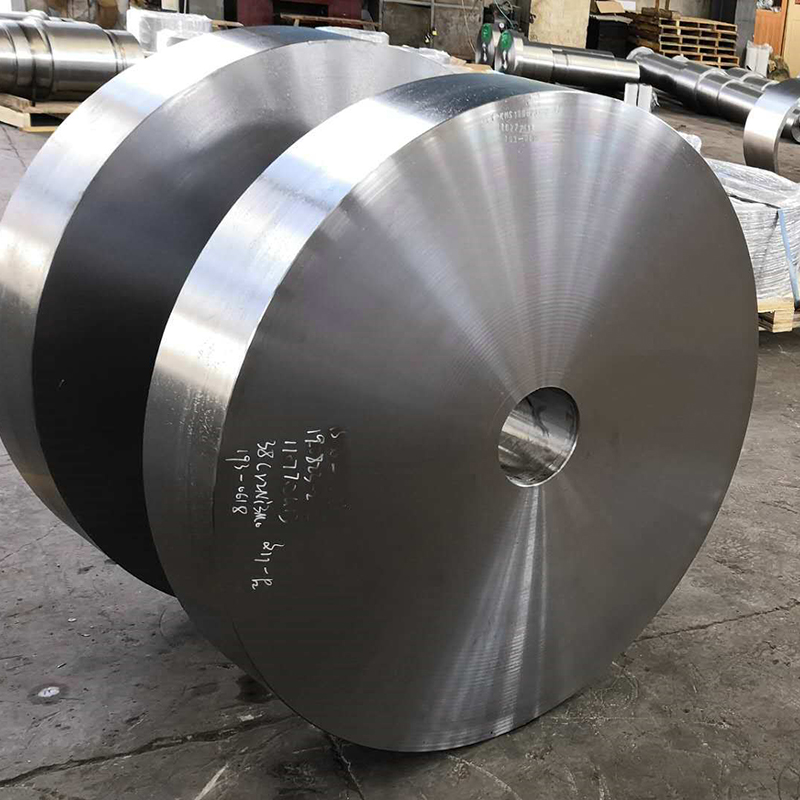

Metallurgical Machinery Forgings

piav 2

Kev piav qhia

Nrog peb cov khoom, koj tuaj yeem cia siab tias yuav ua haujlwm zoo tshaj plaws thiab kev ntseeg siab. Txhua qhov forging yog tsim los rau kev lag luam-cov khoom lag luam cov qauv xws li EN10083, EN10084, EN10085, EN10088 thiab EN10250, kom ntseeg tau cov qauv zoo tshaj plaws. Peb cov khoom siv raw khoom yog tsim los siv cov thev naus laus zis xws li EAF + LF + VD + ingot casting (hauv qab casting), thiab cov khoom kawg yog qhov muaj zog thiab txhim khu kev qha.

Peb metallurgical machinery forgings muaj ntau yam kev siv. Txawm hais tias koj xav tau rotors, shafts, rollers, crankshafts, spindles, eccentric shafts, bevel gears, gears, parallel pinions, flanges, crowns, bushings, tes tsho, couplings lossis crank caj npab, peb muaj koj cov kev xav tau. Peb cov khoom siv dav ua kom ntseeg tau tias peb tuaj yeem ua tau raws li koj cov kev xav tau tshwj xeeb, txawm tias lawv yuav nyuaj npaum li cas.

Ib tug ntawm cov yam ntxwv tseem ceeb ntawm peb metallurgical machinery forgings yog forging piv. Peb cov forgings yog tsim los nrog qhov tseeb thiab qhov tseeb ntawm tsawg kawg 3: 1 lossis zoo dua. Qhov no ua kom pom kev ncaj ncees ntawm cov qauv thiab txhim kho kev ua tau zoo ntawm cov khoom tiav.

Txhawm rau txhawm rau txhim kho lub zog thiab ua haujlwm ntev ntawm forgings, peb tau txais cov txheej txheem kev kho cua sov nruj. Qhov no suav nrog normalizing, quenching thiab tempering, kev daws teeb meem ntawm stainless hlau los yog kev ntxhov siab nyem ntawm lub rotor los yog ncej. Cov txheej txheem no pab tsim cov qauv sib xws thiab zoo ib yam metallographic qauv, ua rau forgings uas tiv taus tawg, tawg, shrinkage kab noj hniav, pinholes thiab vuam teeb meem.

Txhawm rau kom ntseeg tau qhov zoo ntawm forgings, peb ua raws li ASTM E45 metallographic qauv qauv. Qhov no ua kom cov qoob loo loj ntawm 5 lossis zoo dua, qhia txog kev nplua thiab zoo li microstructure. Peb muaj kev txaus siab heev hauv kev muab cov forgings uas tsis muaj qhov tsis zoo thiab tsis zoo, muab kev thaj yeeb rau koj lub siab tias peb cov khoom yuav ua tau zoo tshaj plaws hauv koj daim ntawv thov.

Zuag qhia tag nrho, peb cov tshuab metallurgical forgings qhia peb txoj kev cog lus kom xa cov khoom zoo tshaj plaws thiab kev ua haujlwm zoo. Nrog rau ntau yam kev siv, cov ntaub ntawv zoo, cov txheej txheem tsim khoom thiab kev tswj xyuas zoo, peb cov forgings yog qhov kev xaiv zoo tshaj plaws rau txhua qhov kev xav tau ntawm cov tshuab metallurgical. Xaiv peb cov forgings thiab paub qhov txawv ntawm kev ua tau zoo thiab kev ntseeg tau.

Tsev

Tsev